Bioplastics – an environmentally friendly alternative to traditional petro-plastics. I will be exploring the potential of bioplastic and how it could be used in art and architecture.

There are 3 different types of ‘environmentally friendly’ plastics that are refered to as bioplastics:

BIODEGRADABLE PLASTIC – these are plastics made from traditional petrochemicals but they are engineered to decompose faster.

ECO/RECYCLED PLASTIC – made from recycled plastic materials instead of raw petrochemicals

BIOPLASTIC – made from natural materials like corn (this is what I will be focusing with)

40% of plastic produced globally is single-use

It is more important now then ever before that we find an alternative to the oil-based plastics that are polluting are planet.

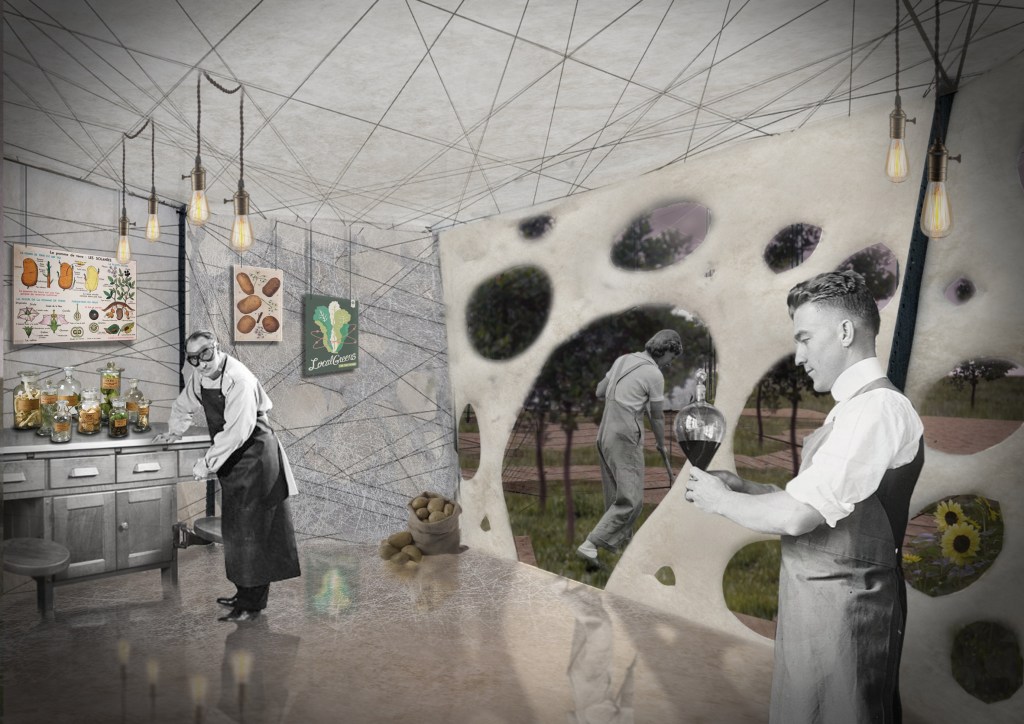

Bioplastics offer endless opportunities to replace petro-plastics. Bioplastics are made from materials found naturally and so they are better for the environment. Bioplastics can typically decompose in soil or landfill within a few months; a small fraction of the time it takes petro-plastic to decompose. Bioplastics can be made from waste materials like hair, potatoes that aren’t edible, seaweed etc. This means that we could reduce our waste and create an alternative to petro-plastic at the same time.

Bioplastics could also be used to provide us with vitamins and nutrients by bio-engineering. We could soon survive solely off enginered bioplastic.

Sounds perfect – what’s the catch?

Starch-based bioplastics are often made from maize and corn and there are concerns that land previously used for growing food is now being used to ‘grow plastics’. By 2014 almost a quarter of US grain production was expected to have been turned over to biofuels.

Increased production of biofuels could lead to rising food costs and increasing poverty.

Growing crops for bioplastics still uses crude oil based products to power farming machinery. Intensive agriculture also adds to greenhouse gas emissions and there can be water pollution from the use of fertilisers. So, bioplastics are not quite as green as they may seem.

According to explainthatstuff.com ‘In some cases, these indirect impacts from “growing” bioplastics are greater than if we simply made plastics from petroleum in the first place’.

Extracting the starch from the plant and converting it into plastic is also highly energy intensive process. A starch-based plastic bag can often end up being more energy intensive and cause higher emissions than an oil-based bag.

Recycling and disposing of bioplastics can also be an issue; bioplastic cannot be recycled alongside normal plastic. If recycled together the bioplastic will make the other plastic unrecyclable as the end product will be chemically unstable.

However, bioplastics are still a more environmentally friendly option when compared with normal plastic as they can decompose in a few months in landfill or a compost bin.

Switching to bioplastics – A case study

Seasonaly the National Trust sends out magazines to their 5 million members, typically wrapped in a polywrap packaging. Recently the National Trust switched to a potato-based bioplastic wrapper in order to cut down on their environmental impact. The new wrapper can be put into the compost bin where it will decompose within a few months, compared to oil-based plastic which can take up to 500 years to decompose in landfill.

The National Trust are leading the way for corporate organisations by cutting down, and eventually eradicating their use of single-use plastics. This is an important issue as 40% of plastic produced globally is single-use; only used once before being thrown away.

The potential applications of bioplastic

Designed by architect Maria Vergopoulou this concept for self-build microhomes would enable people to grow their own homes. The pod-like homes would be made from thin bioplastic layers.

Designed by Iratzoki Lizaso, these chairs are the first on the market to be manufacture using bioplastic.

These Reebok trainers were launched in August 2018 as part of a sustainability initiative called ‘Cotton and Corn’. The trainers have a corn-based bioplastic sole, an alternative to the petroleum-based rubber-soles typically used in trainers. 75% of the shoe is classed as bio-based content.